Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

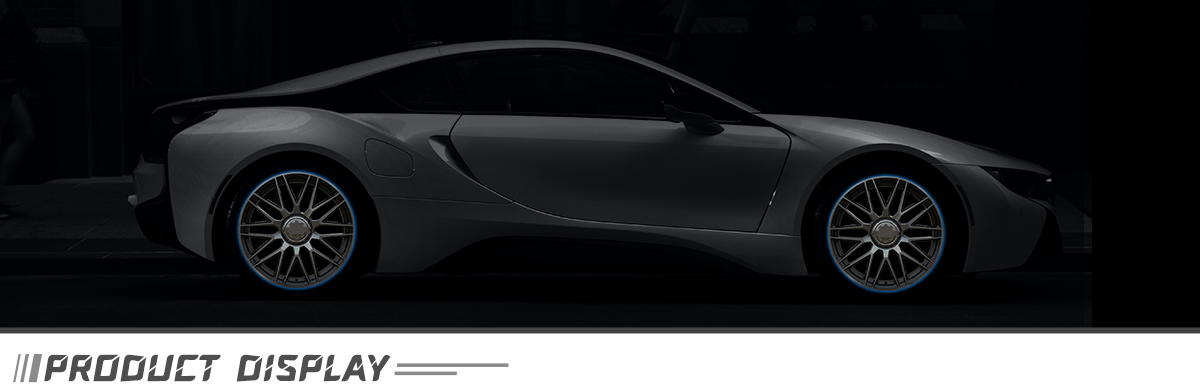

Alloy wheel for 2020 New LEXUS ES300 - Code 1110

The Alloy wheel for 2020 New LEXUS ES300 is designed with your safety in mind. Crafted by expert manufacturers, these wheels are built to meet the highest standards for quality and performance.

FITMENT SIZE ET PCD CB

LEXUS 2185 45 5*150 110

A wheel is an important part of a car. It can be divided into steel material and aluminum alloy wheels. The composite material mainly refers to carbon fiber. The wheel hub of this material has high cost, is not easy to promote, has complex manufacturing process and high technical difficulty and is not suitable for use in household cars. Common household car wheel materials are mainly steel and aluminum alloys. Compared with aluminum alloy, although steel has high strength, its weight is relatively large, and it cannot fully adapt to the development of lightweight automobiles; at the same time, the appearance of steel wheels is not as beautiful as aluminum alloy wheels; aluminum alloy wheels can release more heat so they are widely used in automobiles today.

Features of Alloy wheel for 2020 New LEXUS ES300

The Alloy wheel for 2020 New LEXUS ES300 is designed with your safety in mind. Crafted by expert manufacturers, these wheels are built to meet the highest standards for quality and performance.

Advantages

Constructed from lightweight yet sturdy alloy materials, this wheel is engineered to provide superior handling, stability, and responsiveness on the road.

FAQ

Q: How do you guarantee the quality of your products?

A: Our production is passed the JWL VIA test.

Q: Are you a factory or a trading company?

A: Trading company.

Q: Where is your factory?

A: We have 12 factories working on our order.

Influence of aluminum alloy wheel structure on strength

The forming methods of aluminum alloy wheels include casting method, forging method and spinning method, and different manufacturing methods have different advantages. After modification, the strength of forged and cast wheels tends to increase, but the thickness is very thin, reflecting the increasingly lightweight wheels. However, the larger the size of the hub, the higher the probability of fracture; in general, the degree of thickness affects the strength of the hub for the equivalent material and service conditions, that is, the greater the thickness, the stronger the hub. Taking the cast aluminum alloy wheel as an example, in order to improve the strength of the wheel, other problems may be ignored. For example, the wheel may break after a large impact.

Calculation method

The influence of the thickness of the wheel hub on the strength is self-evident. If the thickness is relatively thin, the wheel hub may have a fracture accident. The representative case is the Dongfeng Yueda Kia K5 wheel hub fracture incident. This fracture incident shows that the thickness of the wheel hub has a great influence on the strength. People in the industry have conducted research and analysis and found that the thickness of the wheel hub of some cars is very thin, not even reaching the standard value of 4.4mm. Although such a wheel hub is very light, it is However, it shows that the production of the wheel hub is not up to standard.

Generally, the thickness of an aluminum alloy wheel should be kept between 5-10mm. If it is lower than this range, it means that the thickness of the hub is not up to standard. The quality of the wheel hub is related to the safety and reliability of car driving. If the thickness does not meet the standard, there will be a danger. Therefore, the car manufacturer needs to determine the thickness reasonably according to the structure and shape of the car wheel, and ensure that the thickness of the wheel is not less than the standard value, otherwise, Various unexpected situations will occur, such as fractures; if the thickness is too thin, more serious bursts may occur, and the vehicle will be affected by external forces when it rotates at a high degree. If there is not enough thickness, it is difficult to resist external force interference.

It can be seen that the thickness of the wheel hub is closely related to the quality of the wheel hub, and there can be no neglect. Pay attention to the thickness of the hub and ensure that the strength of the hub meets the requirements, so as to make driving safer and more secure. Automobile manufacturers should reasonably determine the thickness of the wheel hub according to the industry reference value; consumers should choose the wheel hub carefully, and use the thickness as one of the reference standards for selection.

Aluminum alloy wheel strength requirements

It is a mandatory requirement to measure the strength of aluminum alloy wheels based on the provisions of Japan's JWL/VIA. Germany's aluminum alloy wheel strength regulations are TUV certification, as well as the United States DOT certification. There are certain differences in the certification of these three regulations. Even for the same wheel, there will be many differences under the regulations of the three requirements. At present, China's aluminum alloy wheel strength regulations mainly refer to and follow the above three certifications, and the highest standard is the German certification.